Polycarbonate (PC) is a very strong, lightweight and transparent thermoplastic with a Rockwell hardness of R 121, It harder than PMMA, ABS and PLA. Polycarbonate for 3d printing can withstand tensile and torsional stresses that can break, deform or crack other materials. The polycarbonate for 3d printing is malleable when it cools and can bend without breaking. The material properties of polycarbonate plastic 3d printing make it the most commonly used industrial thermoplastic.

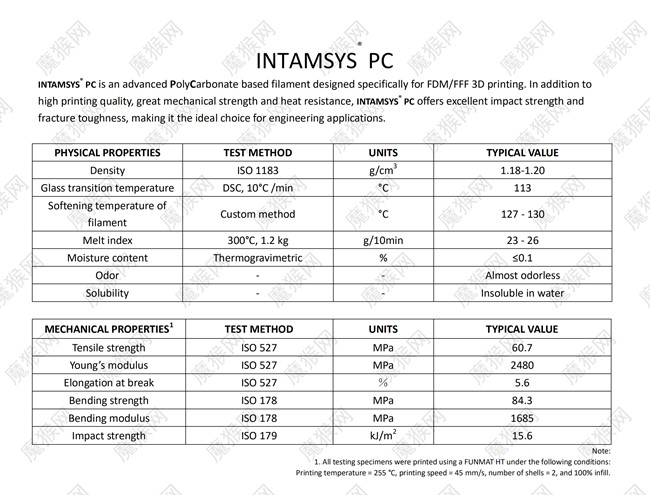

Polycarbonate material is a true thermoplastic material with all the characteristics of engineering plastics. It has the characteristics of high strength, high temperature resistance, impact resistance, bending resistance and so on. The surface is layered with general accuracy and can be used as the final parts. The prototype made of PC material can be directly assembled and used, which is widely used in transportation and home appliance industry. The strength of PC is about 60% higher than ABS material, with super engineering material properties! PC material has strong mechanical properties, tensile strength, bending strength is very good, temperature resistance up to 140℃.

● Unique FDM processing technology makes its surface has obvious layer thickness texture;

● Accuracy control 0.1mm, after processing deviation;

● Can be polished, electroplating, painting, splicing;

● Monochrome, not full color printing. It is not suitable for the design with high requirements for details or rich surface texture;

● The minimum thickness can be 0.127mm;

● Limited aperture, thin wall > 1mm;

● Suitable for thread;

● General water tightness;

Automobile industry

Aerospace

Medical instruments

3D Printed like White (Polycarbonate 3d Printing materials.)