Vacuum assisted casting prototyping process is a process used to create hollow objects. Many vacuum casting manufacturers use die casting vacuum system because it is cheaper than other methods, such as sand casting and investment casting.

In order to understand how vacuum casting prototyping method works, it's important to know what a mold looks like. For vacuum casting manufacturers, a mold is made by pouring molten metal into a carved piece of stone or metal that has been carved into the shape needed for your object. The molten metal will take on the exact same shape as your carved piece when it cools down and hardens in place.

The vacuum casting process consists of the following steps:

Molding

Flashing and trimming

Venting and degassing (optional)

Cooling (optional)

Release agent application (optional)

Sealing the mold and degassing again if necessary (optional)

Casting materials such as silicon rubber are applied over a surface that has been coated with release agents to allow for easy removal of the finished product after it has cured.

Vacuum casting service is a versatile process that is often used to form metal parts and products in industries such as aerospace and automotive. Vacuum casting service can also be used in other applications where a need for large numbers of complex parts, small detail, or both exists. For example, vacuum casting suppliers can produce small intricate details on components that may be larger than their traditional counterparts. This allows vacuum casting manufacturers to produce complex shapes without fear of warping or bending under pressure when they're assembled into finished products. You can use vacuum casting for a variety of applications. Among the most common are:

Automobile parts. Vacuum casting service is used to make automotive parts such as brake calipers, suspension parts and engine covers.

Medical devices. Vacuum casting service is used to create medical devices such as surgical pins, dental implants and nasal stents.

Vacuum casting service has become very popular due to its ability to create high-quality production runs at low cost while using less energy than traditional steel-forming processes like machining or stamping (it's much faster too!). As such, it's become the preferred method for creating certain types of vacuum casting metal products like pipes which require precise tolerances; this method will eliminate costly downtime from manufacturing because there's no need for rework once the pieces are casted properly before assembly takes place.

Send the 3D file and surface finishing request to China vacuum casting factory Proto Mold email

Production will commence upon receipt of order confirmation and down payment records

The lead time is 7 working days , But it depends on the parts size, quantity and material options

The finished vacuum assisted casting product will be delivered to the Customer address at the scheduled time, including overseas service.

Vacuum casting material is also known as polyurethane resin, The types of ABS materials are PX8150, DPI860, PX5118, Similar to PC material PX520, PX527; Rapid prototyping environmental protection material UP590; PP/PE material PX100,PX215; High temperature resistant castable PX223 and 6160, similar to sub-afterforce PX521 and excellent performance of 8400 soft rubber resin,8150PU Resin and so on, collectively referred to as composite materials.

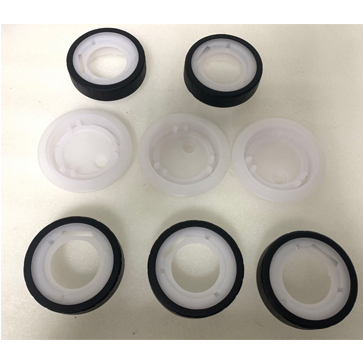

Silica gel mold is one of the ways to make a prototype. It has the advantages of fast time, less cost and low probability of processing failure. More than 20 of the same products can be made using a single silicone mold. Silicone mold production steps can be divided into three steps.

Prototype Before making silicone mold, we need to make a prototype. Prototype can use more common ABS material, CNC processing can be.

After the silicone mold prototype is ready, start to make the silicone mold. After eight hours of drying, the silicone mold is cut open and the prototype is removed. At this point, the silicone mold is ready.

Injection type Inject the liquid gum material into the silica gel mold and dry it. The service life of silica gel mold is about 25 mold times.

Shrinkage and easy deformation. Because the vacuum mold uses the principle of thermal expansion and cold contraction, if we do the hand plate according to the size of the customer's drawings, the liquid in the silica gel mold will shrink some after cooling, resulting in deformation. Vacuum mold is generally used to do the hand plate, and when doing the silica gel mold, it is necessary to do a little bigger than the size. But even so, the error of the hand plate out of the vacuum mold is relatively large, usually in 0.2mm or even larger.

The silicone mold does not deformation and shrink; High temperature resistance, They can be used repeatedly after mold forming; Facilitate the production of products

The silicone mold is of high quality and low price, the production cycle is relatively short, and the unnecessary loss can be prevented before opening the mold.

Production cycle of 3-7 days fast delivery, accuracy can be as high as ±0.1mm, suitable for small batch customization within 1000.

It is widely used in medical, robot, auto parts, digital, home appliances and other industries.