3D printed nylon parts can be used for product verification or directly used as functional products. The product is 3D printing with light weight and shorter production cycle. It has great application space in automobile, aerospace, art creation, medical treatment and other fields. SLS products have many surface pores after forming, and the surface roughness is about Ra12.5. The surface roughness, finish and coloring of SLS products cannot meet the requirements of practical use.

ylon material, as a classic material, is famous for its excellent durability, high specific strength, high toughness, low wear resistance and corrosion resistance, and has been widely used in the field of processing and manufacturing.

Nylon is a name for Polyamide fiber. It's called PA . For some users who often use PLA, PLA printing is flexible, suitable for many occasions, and It has the general strength required for ordinary occasions, but when it is used in professional occasions, it will find it is not suitable. PLA printed parts cannot be exposed to sunlight for long periods of time and are not suitable for applications above 100°C. If ABS is used for 3D printing, it will be found that it is more durable than PLA. However, 3D printed ABS parts are usually not as strong as injection parts, and printed parts are generally not strong enough due to the adhesion between layers.

Nylon consumable is a kind of high strength, very durable 3D printing consumable. Very tough, at the same time good adhesion between layers, more solid than ABS consumables.

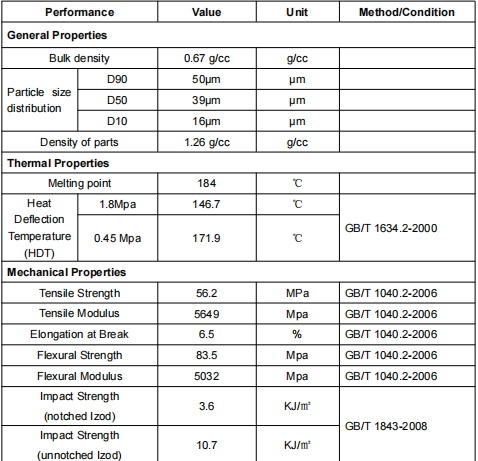

Nylon has excellent mechanical properties. Its tensile strength, compressive strength, impact strength, rigidity and wear resistance are better, suitable for manufacturing some need to high strength, high toughness products. However, its mechanical properties are greatly affected by temperature and humidity, and its tensile strength decreases with the increase of temperature and humidity. Nylon has good impact properties. It increases with the increase of temperature and water absorption, and hardness decreases with the increase of water content.

Under low temperature and dry conditions, nylon has good electrical insulation, but under wet conditions, its volume resistivity and dielectric strength will decrease, dielectric constant and dielectric loss will increase obviously. In both FDM and SLS process, the interference of electrostatic generated by friction of nylon powder should be avoided.

Nylon is a kind of polymer material with strong polarity. Hydrogen bonds can be formed between molecules, so the melting temperature is relatively high, and the melting temperature range is relatively narrow, and there is an obvious melting point. Compared with other polymer materials, the molecular weight of nylon materials is usually smaller, so the thermal deformation temperature is lower, generally below 80C. Because the melting temperature of most nylon is much higher than the thermal deformation temperature. The melt viscosity of nylon is low. Unable to meet the requirements of FDM printing, FDM review requirements, so nylon materials mostly adopt SLS process for printing.

Nylon has good chemical stability, crystallization and high cohesion, insoluble in common solvents, because it can withstand many chemicals, so not acid, alkali, ketone, alcohol, grease, grease, lubricating oil, gasoline. Salt water and detergents. At room temperature, nylon dissolves in a saturated solution of certain salts and in some strongly polar solvents. It also shows good stability to certain bacteria, so it can be used for printing some biomedical devices.

Nylon with weather resistance is general, if it is exposure to the atmosphere long time that will become brittle, mechanical properties decreased significantly, adding carbon ash and stabilizer can improve its weather resistance.

At present, several modifications are helpful to provide comprehensive properties of NYLON materials for 3D printing. Reduce water absorption; Provide dimensional stability; Improve flame retardant; Improve mechanical properties; Improve low temperature brittleness; Improve wear resistance; Reduce costs.

complex and thin-walled pipes (electric tools, aerospace equipment).

Shell products.

Impeller and connector.

Sports consumer goods.

Car dashboard and lattice window.

Assembly design.

Functional prototypes close to the performance characteristics of the product for final use.

Suitable for small and medium volume rapid manufacturing.

Requirements for medical applications that are USP Class VI or bioadaptable.

Parts processed by lathe or bonded by adhesive.

Complex products and plastic prototypes.

Appearance, structure or functional prototype.

Nylon-like White (Accura SLS 3200)

Nylon-like Black (Accura PA 12)